What is Pressure Die Casting?

Pressure die casting involves forcing molten metal under pressure into a mould cavity. These moulds or dies can produce complex shapes with immaculate accuracy and precision compared to sand casting methods. mainly used for products produced in very large quantities.

Pressure die casting is a method used for precision parts and smoother surface finishes that our customer requires. It is the preferred manufacturing process for high specification components with complex shapes. In combination with our expertise and experience, we can achieve a near perfect surface finish and eliminate porosity. As the dies will need to be separated to eject the part however, certain designs and shapes are not recommended. Investment casting may be more suitable for these types of castings.

Pressure die casting requires high capital expenditure to manufacture the dies. However, if your item is to be produced in very large quantities, it can be a very economical decision to use this casting method, even if precision or surface finish is not a priority.

If you are unsure which casting method is most applicable to you, don’t hesitate to contact us for any questions. We will be more than happy to assist you!

Pressure Die Casting Advantages

-

Very low operational cost compared to other manufacturing methods. Pressure die casting is ideal for high volume production runs and easily automated!

-

Custom shapes and designs are available for die casted parts in addition to standard designs.

-

Die casted parts are extremely strong and functional, ideal for high stress environments and safety applications.

-

Secondary processes such as machining and hardening may be further applied improve functionality or material properties.

-

Pressure die castings have superior mechanical properties, especially in thin walled structures.

-

Low cost tooling! Adarsh Australia produces their tools in-house to reduce tooling costs and ensure tool quality and durability.

Contact us to find out more about our pressure die casting services or to get started with your project today!

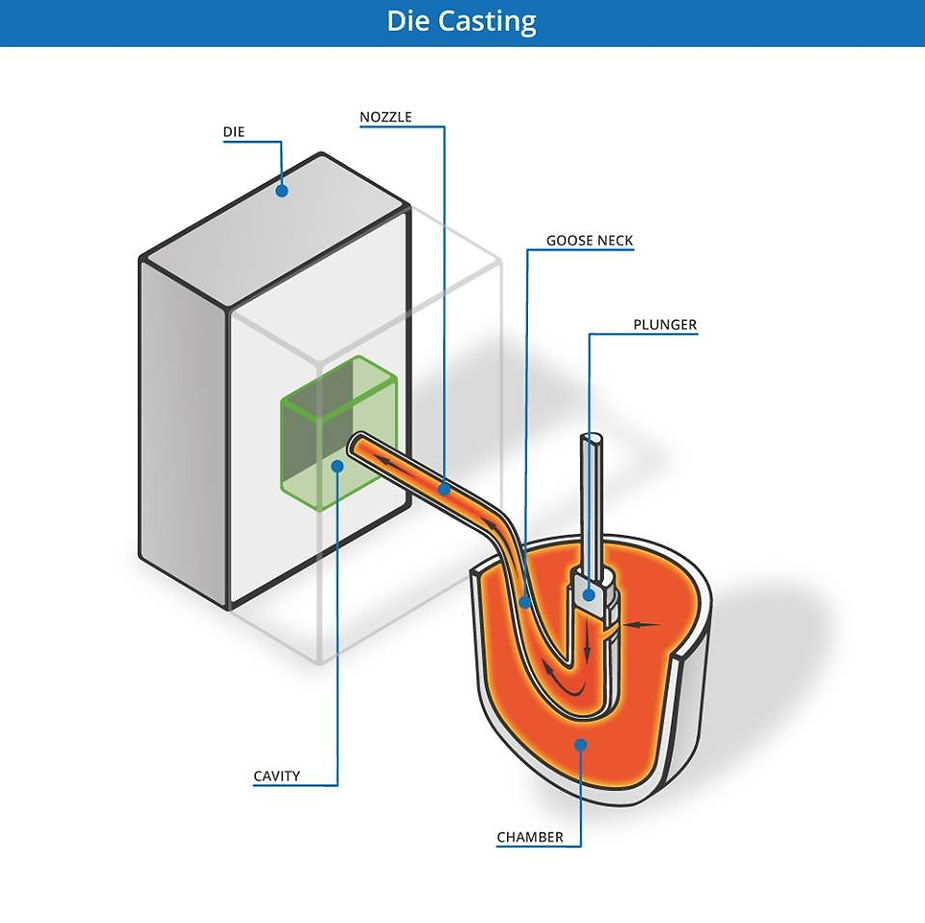

Pressure Die Casting Process

We have developed the following illustration to describe our pressure die casting process to our customers:

Metals Used in Pressure Die Casting

Many different types of ferrous and non-ferrous metals/alloys are used in pressure die casting. Adarsh Australia has worked with a wide variety of metals before and know all the in's and out's of die casting each specific material. Common metals and alloys for pressure die casting include:

-

Aluminium

-

Zinc

-

Zinc alloys

-

Copper

-

Lead

-

Tin

Parts manufactured in Adarsh Australia through pressure die casting have great dimensional accuracy, smooth surface finish and are of excellent quality. We have years of die casting experience under our belt so you can depend on us to meet your manufacturing needs!

If you have any questions, contact one of our metal casting experts over the phone or at our Perth office! We will be happy to answer any questions you may have.