What is Sand Casting?

Sand casting is the art of creating metallic parts by pouring molten metal into a cavity formed by a recyclable sand mould. Firstly, a re-usable pattern is manufactured that can be used to form the cavity in moulding sand. The pattern is then removed from the moulding sand which holds its shape. Molten metal is then poured into the cavity left by the pattern in the sand. When the metal cools and solidifies, the sand is broken apart to reveal the product!

Sand casting is one the most common and economical casting options for low volume production of simple parts. Items such as gears, pulleys, propellers, ingots and automotive components are commonly produced using sand casting methods. Sand castings can also be very large!

Contact our casting experts to find out if sand casting is suitable for your product!

Sand Casting Advantages

-

Sand casting is a very economical method of manufacturing for low volume runs.

-

Sand casting allows for the production of very large parts that cannot be achieved via other methods of casting.

-

Sand castings can be made of almost any type of metal and alloy, including ferrous and non-ferrous metals!

-

Moulding sand used in sand casting is reusable!

-

Low cost tooling! Adarsh Australia produces their tools in-house to reduce tooling costs and ensure tool quality and durability.

We have all the capabilities to assist you through your sand casting project.

Contact us to get started right away!

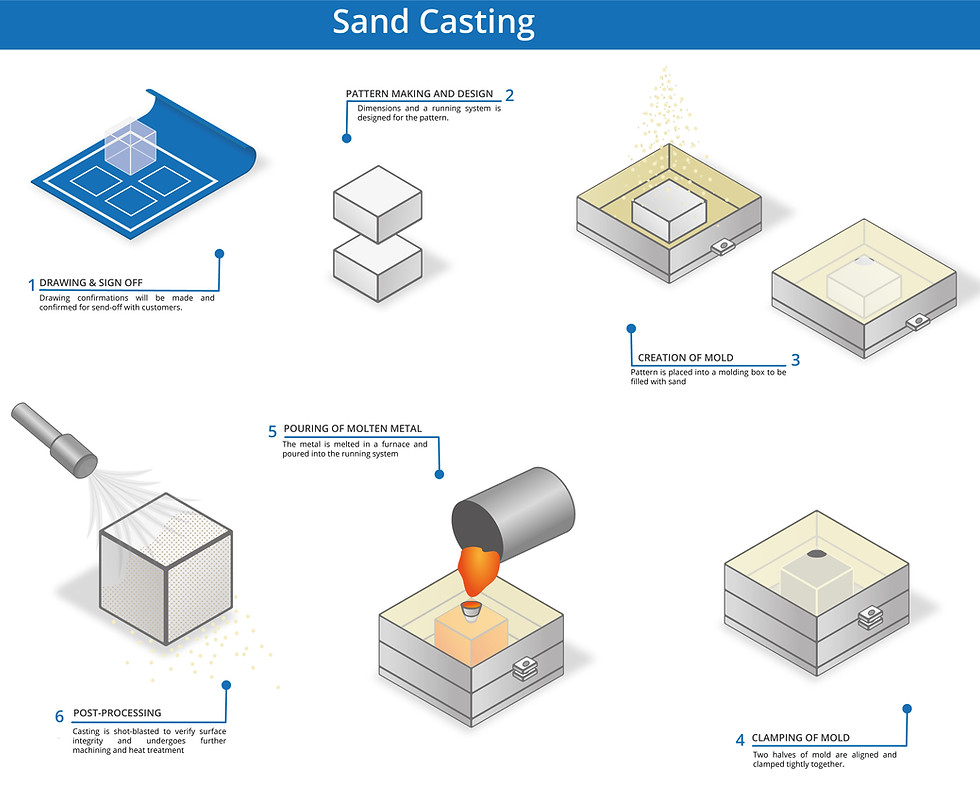

Sand Casting Process

We have developed the following illustration to describe the sand casting process to our customers:

Metals Used in Sand Casting

One of the main advantages for sand casting is that almost every type of metal and alloy can be used due the simplicity of the process. Adarsh Australia has worked with a large range of metals and has observed the most common metals and alloys to be:

-

Stainless steel

-

Carbon steel

-

Alloy steel

-

Aluminium and aluminium alloys

-

Copper

-

Zinc

-

Tin

-

Brass

-

Bronze

-

Magnesium

-

Nickel

-

Lead

-

Titanium

The choice of material will depend on the application of the product to be cast and its associated technical requirements. The choice of material and the required surface finish will also affect the type and composition of the sand mixture used to create the mould.

Adarsh Australia’s in-house sand casting design and engineering expertise coupled with our high-end multi-process manufacturing facilities located locally in Western Australia and overseas, are second to none. Whether your sand casting needs are for application in agriculture, marine, automotive, or any other number of industry sectors, Adarsh Australia will work with you to ensure the best sand casting design and manufacture solution.

If you are unsure of which material will suit your application best don’t hesitate to contact one of our metal casting experts over the phone or at our Perth office!